The OmniScan® iX is an industrial ultrasonic flaw detector system designed for the high-speed testing of critical industrial components.

The compact OmniScan iX is housed in a rugged benchtop casing and is also available in a rack-mount version or with a swivel-arm assembly for easy integration into a production system.

The OmniScan iX is central to your industrial component testing system. Olympus provides all the software libraries required to enable the integrator to tie in your existing process control system.

In addition, we provide the user interface ports necessary to connect a display, keyboard, mouse, and external storage. The real-time programmable alarm and analog outputs, and the encoder outputs, enable easy integration of the mechanical and electronic components of your industrial process.

All that is needed for rapid and efficient component testing is built-in!

Complete Integrated Solution

Software Features

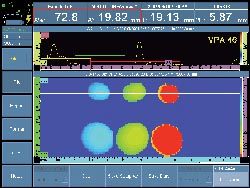

Strip Chart View

Full-Featured C-Scan Software

Hardware Features

Channel Configuration

The OmniScan iX can be configured for pulse-echo, pitch-and-catch, or sequence firing.

Component Testing

Component testing is typically performed under an assembly-line environment. The OmniScan® iX is used to accept or reject (go-no-go testing) thousands of parts a day. Multichannel instrument configurations lend themselves very well to assembly-line applications, which are aimed at detecting flaws within the various zones of a part-not just under one particular area with one transducer. 16 alarm outputs on the OmniScan iX allow the tracking of a particular zone and monitoring the zone that is giving the alarm conditions.

Engine-Disc Inspection

Critical inspection of turbine engine discs requires a very sensitive ultrasonic flaw detector capable of detecting small defects in difficult nickel-

The OmniScan iXhas been qualified by GE Aircraft Engines and added to the DFO as follows:

Hardware Options

OMNI-IX-A-RACK1: OmniScan iX rackmount bracket option

OMNI-IX-A-SWIV: OmniScan iX swivel-arm assembly

OMNI-IX-A-SCASE: OmniScan iX hard carrying case

OMNI-IX-A-ACC1: OmniScan iX accessory kit includes the following:

Software Options

OMNI-IX-SO-ENC1: OmniScan iX software option to activate two encoder inputs on the instrument

OMNI-IX-SO-BEA: OmniScan iX software option to activate back wall echo attenuator on the instrument

Standard Inclusions

| Overall dimensions (W × H × D) | Benchtop version | 375 mm × 238 mm × 185 mm (14.75 in. × 9.4 in. × 7.3 in.) |

|---|---|---|

| Rack mount version | 485 mm × 222 mm × 190 mm (19 in. × 8.7 in. × 7.5 in.) | |

| Weight | 6.5 kg (14.3 lb) | |

| Connectors | BNC (2, 4 or 8) | |

| Pulser/Receiver | Number of pulsers/receivers | 2, 4 or 8 |

| Pulser | Pulse output | 50 V, 100 V, 200 V, 300 V ±10% |

| Pulse width | Adjustable from 30 ns to 1000 ns ±10%, resolution of 2.5 ns | |

| Fall time | Less than 7 ns | |

| Pulse shape | Negative square wave | |

| Output impedance | Less than 7 Ω | |

| Receiver | Receiver gain range | 0-100 dB, by steps of 0.1 dB |

| Maximum input signal | 20 V p-p (screen at 128%) | |

| Minimum sensibility | 200 μV p-p (screen at 128%) | |

| Noise referred to input | 160 μV p-p (26 μV RMS) (128%) | |

| Input impedance | 50 Ω | |

| Input filter ( bandwidth) | Centered at 1 MHz (1.5 MHz), centered at 2 MHz (2.25 MHz), centered at 5 MHz (4 MHz), centered at 10 MHz (12 MHz), centered at 15 MHz, centered at 20 MHz, 0.25-2.5 MHz, 2-25 MHz BB | |

| Bandwidth of the system | 0.25-35 MHz (-3 dB) | |

| Rectifier | Both, positive, negative, none | |

| Mode | PE (pulse-echo), PC (pitch-and-catch), TT (through-transmission). In P-P mode the maximum of number of pulsers equals the number of channels/2 | |

| Smoothing | Digital | |

| TCG | Number of points | 16 |

| TCG range | Up to 40 dB | |

| Maximum gain slope | 20 dB/μs | |

| Data acquisition | A-scan acquisition rate | 6000 A-scans/s (PRF/N, where N = number of channels) (512-point A-scan) |

| Maximum pulsing rate | 12 kHz (C-scan + Alarm mode). Up to 6 kHz with full A-scan recording | |

| Data processing | Real-time averaging | 2, 4, 8, 16 |

| Gates | Quantity | 3 : I (synchro), A and B (measure) |

| Synchronization | I, A, B referenced on main bang, B referenced on gate I or A (post-synchronization) | |

| Data storage | A-scan recording (TOFD) | 6000 A-scans/s (512-point A-scan) (3 MB/s transfer rate) |

| C-scan type data recording |

10,000 (A1, A2, A3, T1, T2, T3) (3 gates) 10 kHz (lower frequency for corrosion mapping) |

|

| Data visualization | Refresh rate | 60 Hz |

| Modes | A-scan, B-scan, C-scan, strip charts, multiple A-scans, and TOFD | |

| Data synchronization | On time | 1 Hz-12 kHz |

| On encoder | On 1 or 2 axes divided by 1 to 65,536 steps | |

| Outputs and inputs | Number of alarms | 16 (programmable, hold time and delay, filters for n occurrences) |

| Conditions | Any logical combination of gates | |

| Signal | Amplitude or time of flight of gate A or B | |

| Analog outputs (at full PRF) | 16 (0 V to +5 V) (programmable for each gate) | |

| Digital inputs (DIN) | 4 programmable |

公司名稱(chēng):上海譯哲檢測(cè)科技有限公司

:

手機(jī):

其他推薦產(chǎn)品

Component testing

Aerospace manufacturing

Automobile industry

Welded components

Integrated inspection systems

GE DFO P3TF22, P3TF30, P3TF31, and P3TF35 qualified

Multichannel Ultrasonic Industrial Flaw Detector

The OmniScan® iX is an industrial ultrasonic flaw detector system designed for the high-speed testing of critical industrial components.

The compact OmniScan iX is housed in a rugged benchtop casing and is also available in a rack-mount version or with a swivel-arm assembly for easy integration into a production system.

Designed with the Integrator in Mind

The OmniScan iX is central to your industrial component testing system. Olympus provides all the software libraries required to enable the integrator to tie in your existing process control system.

In addition, we provide the user interface ports necessary to connect a display, keyboard, mouse, and external storage. The real-time programmable alarm and analog outputs, and the encoder outputs, enable easy integration of the mechanical and electronic components of your industrial process.

All that is needed for rapid and efficient component testing is built-in!

Features

Data storage capability (internal and external)

Strip chart display

16 real-time alarms

16 real-time analog outputs (at PRF)

4 digital inputs

Remote control from PC

Multiple A-scans

A-scan and C-scan imaging

19-in., 5U rack-mount version

TomoView?-compatible for data analysis only

Remote control functions, for custom programming

2-axis mechanical encoders

Multiple scan modes, including helicoidal

Multiple channels (up to 8)

TCG/DAC curves

Interface gate for immersion testing

Touch screen

VGA output

Maximum PRF is equal to the PRF divided by the number of channels (up to 12 kHz)

USB ports for keyboard, mouse, printer, and external storage

Back-wall echo attenuator (available at the end of 2006)

OmniScan iX Benefits and Features

Complete Integrated Solution

Affordable price

Rugged construction for industrial environment with rack-mount option

Remote control functions, for custom programming from PC

Optional data library to access A-scan and/or C-Scan on PC, for custom processing

Software Features

Strip Chart View

Each channel can have unique setups for multizone inspection.

Surface following interface gate

Built-in strip chart display and data storage

Multiple A-scans

A-scan and C-scan imaging

TCG curves

Multiple scan modes, including helicoidal

Back-wall echo attenuator (available at the end of 2006)

Monitoring of amplitude, peak position, crossing-level position, and thickness on each gate

Automatic gate synchronizes from previous gate for higher dynamic range of thickness.

A-scan data storage and C-scan postprocessing capabilities

Interface gate for surface following synchronization of measurement gate and/or TCG/DAC curves

Either positive or negative gate on RF signal (independent for each gate)

16 alarms completely configurable on single-gate events or multiple-gate events, filter for n occurrences from one or multiple channels

Customizable color palette for amplitude and thickness C-scan

60 Hz A-scan refresh rate with overlays of envelope and peak inside the gate

Full-Featured C-Scan Software

Hardware Features

Data storage (internal and external)

Multichannel configuration (up to 8 channels)

PRF up to 12 kHz / number of channels

Analog and alarm output compatibility with older systems

16 real-time fully programmable alarms

16 real-time analog outputs (at PRF)

4 digital inputs to remotely control the machine

2-axis mechanical encoders (option)

2-axis mechanical encoder with data acquisition synchronization on mechanical movement

Channel Configuration

The OmniScan iX can be configured for pulse-echo, pitch-and-catch, or sequence firing.

Component Testing

Component testing is typically performed under an assembly-line environment. The OmniScan® iX is used to accept or reject (go-no-go testing) thousands of parts a day. Multichannel instrument configurations lend themselves very well to assembly-line applications, which are aimed at detecting flaws within the various zones of a part-not just under one particular area with one transducer. 16 alarm outputs on the OmniScan iX allow the tracking of a particular zone and monitoring the zone that is giving the alarm conditions.

Engine-Disc Inspection

Critical inspection of turbine engine discs requires a very sensitive ultrasonic flaw detector capable of detecting small defects in difficult nickel-based metals. Such instruments must be able to operate at high gains, with extremely low noise on both the A-scan display as well as the analog output. The OmniScan iX meets these very demanding requirements. Additional OmniScan iX features such as strip-chart recorder, C-scan display, and back-echo attenuator make this a very versatile instrument. The OmniScan iX can easily drop into existing, older test stations, then later transfer to a full functional station to perform on-board mapping/C-scan.

The OmniScan iXhas been qualified by GE Aircraft Engines and added to the DFO as follows:

P3TF22 Longitudinal Immersion Ultrasonic Inspection of Forgings to Flat Bottom Hole Sensitivities

P3TF30 High Sensitivity Ultrasonic Inspection of Forged Fine Grain Powder Alloy

P3TF31 Ultrasonic Immersion Inspection of Powder Metallurgy Extruded Bars and Billets

P3TF35 Side Drill Hole Ultrasonic Inspection

OmniScan iX Options

Hardware Options

OMNI-IX-A-RACK1: OmniScan iX rackmount bracket option

OMNI-IX-A-SWIV: OmniScan iX swivel-arm assembly

OMNI-IX-A-SCASE: OmniScan iX hard carrying case

OMNI-IX-A-ACC1: OmniScan iX accessory kit includes the following:

1 external keyboard,

1 optical mouse,

Software Options

OMNI-IX-SO-ENC1: OmniScan iX software option to activate two encoder inputs on the instrument

OMNI-IX-SO-BEA: OmniScan iX software option to activate back wall echo attenuator on the instrument

Standard Inclusions

OmniScan iX instrument

Ethernet® cable

OmniScan software

User's manual

NDT Remote Control Software Library 2.0

1 storage USB key